Tips for distinguishing between light and heavy calcium

Time: 2018-08-30

As we all know, whether it is heavy calcium carbonate (referred to as heavy calcium) or light calcium carbonate (referred to as light calcium) is the largest and most widely used powder filler in the plastic industry, and the economy of calcium carbonate as a cheap filling material is self-evident. Years of application practice shows that calcium carbonate can not only reduce the raw material cost of plastic products, but also improve some properties of plastic materials.

The distinction between light calcium carbonate and heavy calcium carbonate has always been a problem that bothers most people. Today, Xiaobian will introduce the 13 distinction points of light calcium and heavy calcium.

01 The source mode is different

Light calcium carbonate is chemically synthesized calcium carbonate, also known as precipitated calcium carbonate, colloidal calcium carbonate or active calcium carbonate, and can even produce nano-calcium carbonate, referred to as light calcium. It is the calcination of limestone raw materials to produce lime and carbon dioxide, and then add water to digest lime to produce lime milk, its main component calcium hydroxide, through carbon dioxide carbonized lime milk to produce calcium carbonate precipitation, dehydration, drying and crushing to produce, or by sodium carbonate and calcium chloride double decomposition reaction to produce calcium carbonate precipitation, dehydration, drying and crushing to produce. Heavy calcium carbonate, referred to as heavy calcium, is made by directly crushing natural calcite, marble, chalk, shells, etc.

02 packing density is different

The most obvious difference between heavy calcium and light calcium is that the bulk density of the product is different, the bulk density of heavy calcium products is larger, generally 0.8 ~ 1.3g/cm3; The bulk density of light calcium products is small, mostly 0.5 ~ 0.7g/cm3; Some nano-calcium carbonate products have an even lower packing density, which can reach about 0.28g/cm3. Heavy calcium and light calcium products can also be roughly distinguished by the packaging volume of the product, the general heavy calcium products are mostly 25kg/ package, the product packaging volume is small, and the light calcium products of the same quality are significantly larger, and some nano-calcium carbonate products also use 15kg/ package or 20kg/ package packaging.

In practice, we commonly use the sedimentation volume to measure the density of calcium carbonate. The sedimentation volume is the volume (ml) of calcium carbonate per unit mass after oscillating in 100ml water and standing for 3h. The larger the sedimentation volume, the smaller the product particle size, the lighter the density and the higher the product grade. The sedimentation volume of heavy calcium carbonate is 1.1 ~ 1.4ml/g, the sedimentation volume of light calcium carbonate is 2.4 ~ 2.8ml/g, and the sedimentation volume of nano calcium carbonate is 3.0 ~ 4.0ml/g. Light calcium carbonate, heavy calcium carbonate and nano calcium carbonate can be preliminatively determined by the difference of sedimentation volume.

In fact, the true density of heavy calcium and light calcium composite products is not much different, the general true density of heavy calcium is 2.6-2.9g /cm3, and light calcium is 2.4-2.6g /cm3. It is also said that the true density of the two is the same, but the packing density is different. The reason is that the particle shape of light calcium is spindle shape or jujube stone shape, occupying a relatively large volume; The appearance of heavy calcium is mostly blocky, and the occupied volume is relatively small.

03 Whiteness size is different

Due to the relative impurities of heavy calcium products, the whiteness of the product is generally 89% to 93%, and a very small number of products can reach 95%. And light calcium products because of chemical synthesis, remove a lot of impurities, product purity is very high, so the whiteness is more than 92% to 95%, some products can reach 96% to 97%, which is also the main reason why light calcium products are used for high-grade or light-colored products filled.

04 Different moisture content

The water content of heavy calcium products is generally 0.2% to 0.3%, and the water content is relatively low and stable, and the water content of some high-grade heavy calcium products can even reach about 0.1%. Ordinary light calcium products moisture 0.3% ~ 0.8%, sometimes there will be a certain fluctuation is not stable. Traditionally, the distinction between heavy and light calcium is to test water content with a water component instrument, and water content as large as close to 1% is light calcium, and as small as less than 0.1% is heavy calcium.

05 Different particle size

The particle size of heavy calcium products ranges from 0.5 to 45um, and the particle size of products varies with different crushing equipment. The particle size of ordinary light calcium products is generally 0.5 ~ 15um, because the particle shape is spindle shape, it is difficult to accurately determine, generally a range; The particle size of nano-calcium carbonate in light calcium is finer, and the size is generally 20 ~ 200nm. The particle size of ordinary light calcium carbonate is generally about 2500 mesh, which can meet the performance needs of PVC pipes and profiles, so from the particle size consideration, PVC pipes and profiles are traditionally selected light calcium carbonate. In the past, due to the limitation of crushing equipment, heavy calcium carbonate can not reach this fineness, and now the particle size of heavy calcium carbonate can fully meet the needs, and even finer than light calcium carbonate, so now PVC pipes and profiles can be selected.

06 Smell different

Light calcium due to the calcination of limestone to remove a lot of impurities in general, the whiteness is higher, the purity is also higher, but the domestic light calcium is a lot because the calcium oxide reaction is not complete, residual lime smell, if used in the food industry, such as filling cookies will have a choking smell, and heavy calcium does not. In addition, too much calcium oxide will cause the product to be alkaline in the water-based system or the PH value is not well adjusted, resulting in instability of the finished product.

In addition, the phosphoric acid content of the two is different, and light calcium sometimes needs to add a small amount of phosphoric acid in order to adjust the PH value in a reasonable range, while heavy calcium does not.

07 Different particle shapes

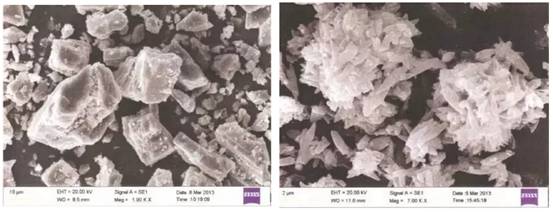

Due to the mechanical crushing and grading of heavy calcium products, the particle shape is generally cube, polygon, cuboid and other irregular forms, as shown in Figure 1. For different heavy calcium processing methods, the microscopic shape of calcium carbonate is different, for example, the calcium carbonate processed by grinding is spindle shape, and the calcium carbonate processed by air grinding is granular shape.

< Previous Next >

When viewed with a high power microscope, the particles of ordinary light calcium are more regular and usually spindle shaped when fully dispersed, as shown in Figure 2. For light calcium carbonate, the particle shape of the synthetic product can be artificially controlled, and a control agent can be added to the carbonization process to achieve control.

Home

Home  News

News The company brother enterprises: Jiangxi Gaofeng Calcium Carbonate Co., Ltd.、Jiangxi Bailui new material Technology Co., LTD

The company brother enterprises: Jiangxi Gaofeng Calcium Carbonate Co., Ltd.、Jiangxi Bailui new material Technology Co., LTD